THE ULTIMATE CUSTOM SLEEPER – ALL THE COMFORTS OF HOME, NO MATTER WHERE THE ROAD TAKES YOU

NEWS & EVENTS

We know it’s challenging keeping up-to-date on current news and events and finding industry specific information relevant to you. That’s why we’ve created this section to offer owner-operators – living and working in a Bolt Custom Sleeper – important and interesting information to be helpful for your business and scheduling.

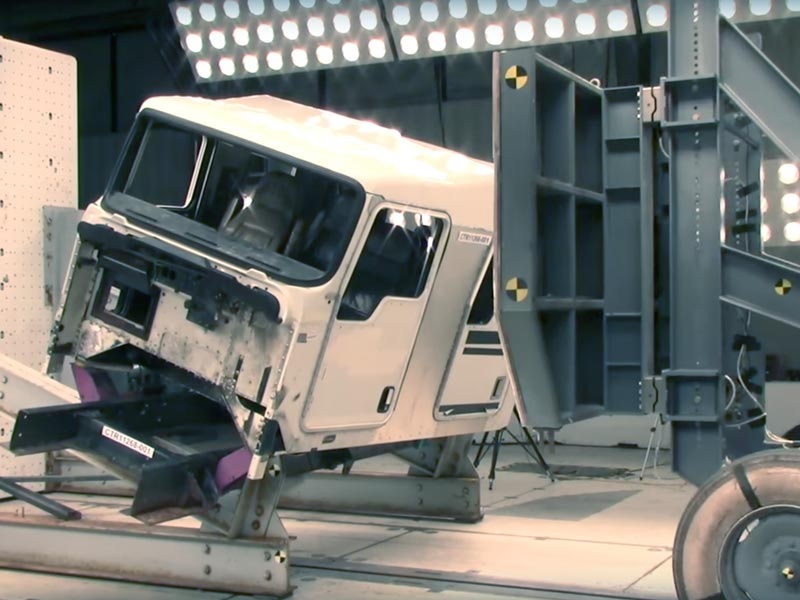

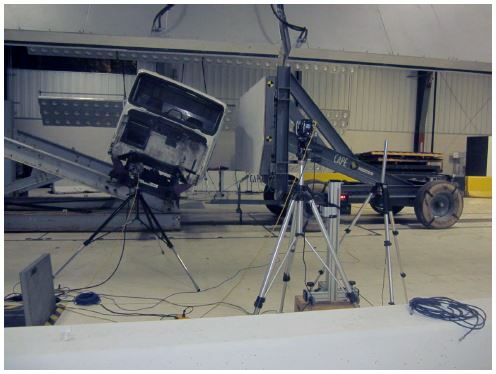

BOLT CUSTOM TRUCKS’ CREW CAB CONVERSION PASSES ROLL OVER CRUSH TEST SIMULATION FOR EMERGENCY VEHICLES

The National Fire Protection Association (NFPA) has determined that vehicles and transportation equipment must meet certain defined standards intended to eliminate death and injuries related to hazards associated with firefighting personnel preventing and fighting fires. Bolt Custom Trucks has just announced that they are building custom crew cabs on Kenworth and Peterbilt brand trucks which have recently been certified under NFPA codes and standards that protect these brave individuals in the case of a rollover crash.

These codes and standards state that a fire truck must be able to endure a rollover accident and the structural cab must stay intact in order to protect the occupants. Specifically, the truck cab must be able to pass a series of roof crush simulation tests, along with, a seat belt pull test performed on the occupant restraints of the five seated positions in the cab.

“We are proud to have engineered and built a cab that meets the full extent of these testing parameters and now offer this crew cab conversion to the marketplace,” said Brian Callan, president of Bolt Custom Trucks. “We know that there are competing companies offering similar crew cab conversions on Kenworth and Peterbilt cabs, and it appears that these competitors are offering their conversions without having passed a third party validation. Unfortunately, this is putting firefighters and other emergency personnel at risk. They are rushing to emergencies in vehicles that are unlikely to survive a rollover accident without the cab becoming crushed and potentially subjecting the occupants to substantial injury or possible death.”

The full extent of these tests was performed by the CAPE testing facility, Center for Advanced Product Evaluation – a division of IMMI. Tests were performed in various stages from November 2 to December 1, 2016 with the full results compiled and published over the succeeding 30 days. Bolt will make full testing results available for customer review upon request.

For the test, Bolt converted a Kenworth day cab truck to a four door crew cab with a 52” extension and sufficient structural support added in the cab’s roof, as well as the A, B and C roof pillars in order for the truck to pass this roof crush test.

Bolt Custom Trucks looks forward to offering superior and safer crew cab vehicles that meet the standards firefighters and emergency personnel expect so they can do what they do best.

For more information, a summary of the crash test is provided below. For a complete copy of the test results, Contact Us.

Summary of Crash Test:

The National Fire Protection Association (NFPA) has published over 300 consensus codes and standards intended to eliminate death and injuries related to the hazards associated with preventing and fighting fires. NFPA Code 1901 defines standards for firefighting apparatus and more specifically NFPA 1901 section 14.3.2.1 defines that all vehicles and transportation equipment shall meet the quasi-static roof strength requirements of SAE J2422.

In order for a truck to demonstrate that it passes these very specific parameters, a destructive test must be performed by an accredited third party test facility under controlled conditions and the test results must be documented and cataloged. Finally, if the truck passes this roof crush test, then the cab’s occupant restraints must still be subjected to a seat belt pull test to verify that the occupant restraints are manufactured and secured in such a way that the occupants will be thoroughly restrained with neither the occupants nor seats having an opportunity to become dislodged.

First, a side impact was performed on the cab by inverting it at 20 degrees and a sled with a vertical wall was slammed into the cab with a force of over 14,000 ft-lbs. During this stage of the test, there was no contact between an occupant and any non-resilient parts of the interior of the cab. All the doors remained shut and the cab remained attached to the chassis frame as required.

For the second part of the test, a quasi-static roof load was imposed on the cab by using a hydraulic press to impose a roof load of over 26,000 lbs. Per SAE J2242 this force shall be at least equal to the maximum rated capacity of the vehicle’s front axle. This test was actually performed in four increments to represent successive GVWR with the maximum force representing the largest potential front axle available for this truck. Once again, the results of this portion of the test were that there was no contact between the occupant and any non-resilient parts of the interior of the cab – in fact there was loss of head clearance. All the doors remained shut and functional while the cab remained attached to the chassis frame as required.

Finally, a seat belt pull test was performed on the occupant restraints of the five seated positions in the cab per FMVSS 207/210. For this portion of the test, three cylinders pull on each seating position with a total force in excess of 7,000 lbs. between the shoulder and lap portions of the seat belts and the force on the seat itself. This pull test is performed on the driver and passenger front seat positions successively and the three rear seating positions concurrently. After the cylinders reach this maximum force, then it must be maintained for minimum of 10 seconds. For all five seating positions our test cab easily met the testing parameters.